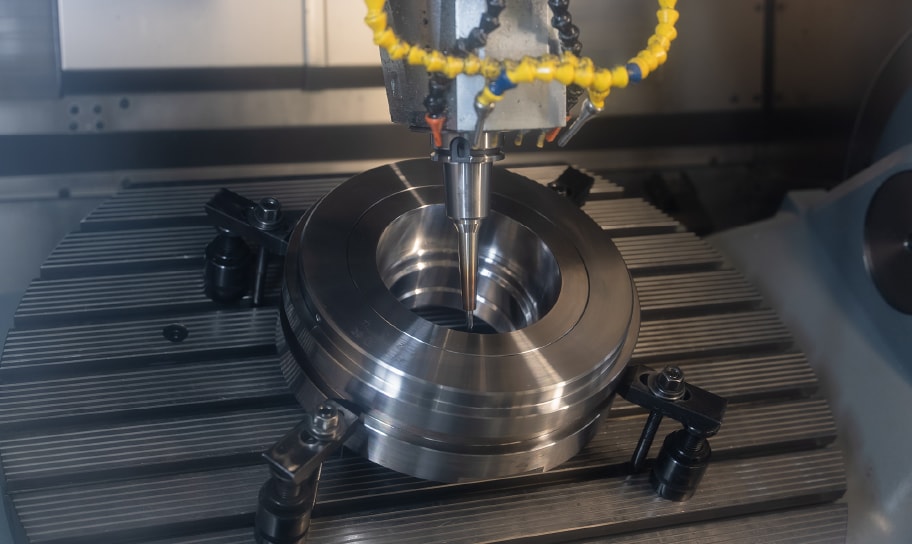

Nagoya Tokushuko provides total engineering with our functions as both a special steel trading company and as a die manufacturer. We can effectively deal with accelerated delivery times.

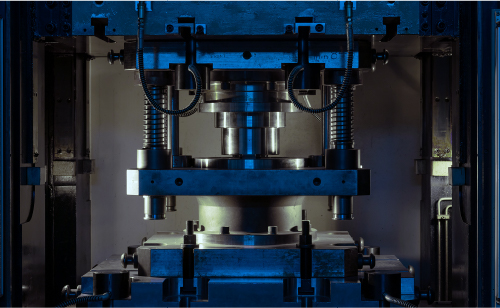

With our functions as both a special steel trading company and as a die manufacturer, Nagoya Tokushuko has the capacity to deliver total engineering that ranges from materials solution to die design, fabrication solution, and die fabrication. Our consistent support from product development to production makes it possible for us to both handle accelerated delivery times and offer high quality. Under our principle of putting the customer first and motto of meeting accelerated delivery times, we have been evaluated as an essential special partner by our customers. Please feel free to contact us for a consultation, whatever your needs may be.

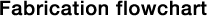

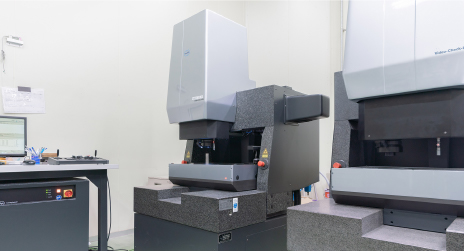

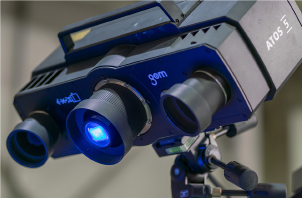

Through reverse engineering, we can create a duplicate of any product to identical precision without a diagram.

As a die manufacturer, we were early to introduce reverse engineering. We can create a duplicate of identical precision with just the product alone, and there is no need for a diagram or specifications. Also, we can produce diagram data using a product in cases where the diagrams or specification documents for the product have been lost due to reasons such as natural disasters like typhoons or heavy rains.

Welding technology that can recycle dies with abrasion and chipping.

In most cases, dies that have abrasion or chipping are often discarded, and a new die is fabricated. At Nagoya Tokushuko, we incorporate welding technology that makes it possible to recycle dies in such conditions. Also, we can further extend the useful life span of products by using special welding materials (welding materials made by Caterpillar of Germany).

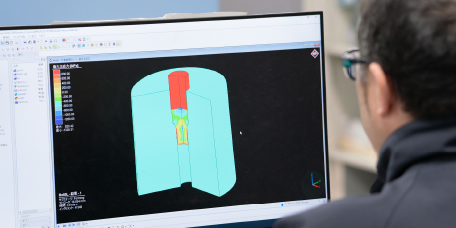

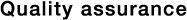

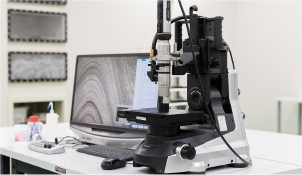

We perform scientific investigations and analyses on the composition and condition of materials and dies.

We conduct analyses on materials and investigations and analyses on the composition and condition of materials and dies, and we incorporate the results into our processing technology.We also thoroughly conduct analyses of the condition of heat treatments and surface treatments, tensile strength, abrasion resistance, and other key characteristics.

Also, by making use of the results of such analyses in combination with our welding technology, we further extend the useful life span of the models we fabricate.

In addition to our domestic network, we have a network of overseas group companies. We have the ability to respond to global needs.

We have subsidiary companies and sales offices located throughout Japan which form our independent network and enable us to respond to customers anywhere in the country. Furthermore, we have production sites located overseas in order to respond to demand from outside the country. We are further reinforcing our system that makes it possible to deal with imports and exports and conduct the local procurement of products. With this group network, we can quickly respond to global needs.